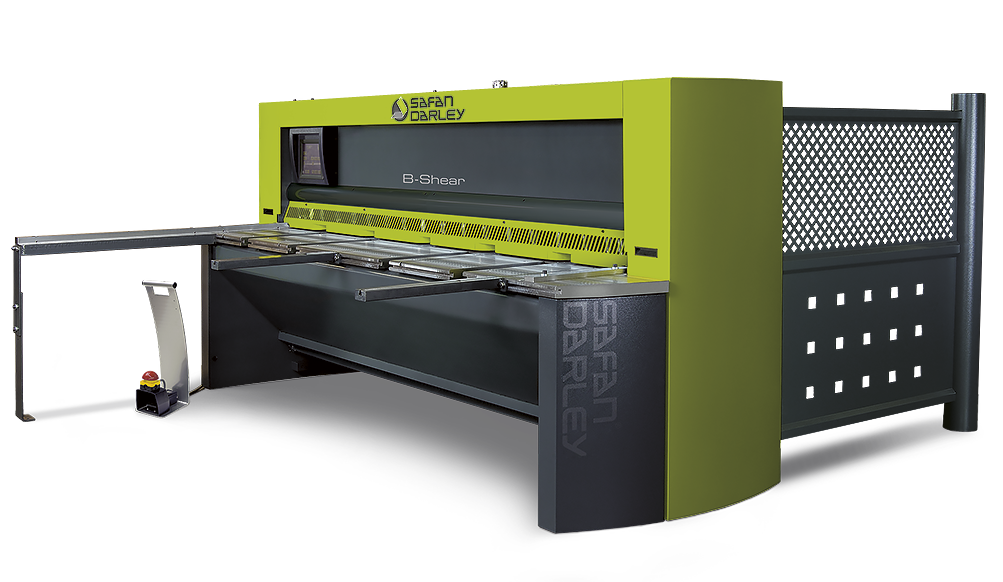

Safan Darley B Shear

The Safan Darley B shear offers a superior integration of hydraulics and electronics. The hybrid drive consists of a servo-electronic motor and a hydraulic pump, a combination that operates in a remarkably quiet and energy-saving manner. The motor only runs when the cutting beam is in motion.

Blades with 4 cutting edges

The standard equipment for the SafanDarley B-Shear includes blades with four cutting edges, on both the top and bottom. They enable you to shear in a very economical manner for several reasons, including the fact that blade wear is spread over the blade’s entire length.

Pneumatic Sheet Support

The standard pneumatic sheet support system makes cutting a little easier, especially when dealing with larger sheet sizes. The sheets to be cut are supported on the back of the shear, ensuring that they can be easily positioned against the backgauge.

Blades with 4 cutting edges

The standard equipment for the Safan Darley B-Shear includes blades with four cutting edges, on both the top and bottom. They enable you to shear in a very economical manner for several reasons, including the fact that blade wear is spread over the blade’s entire length.

Precision and Automatic Compensation

Standard equipment for the Safan Darley M-Shear includes independent left and right clearance adjustment with built-in measuring sensor.

Safety

The shear has extensive guards on the back and sides. These consist of mechanical side covers on the right and left sides plus a photo-electrical guard on the back. The machine’s foot-operated console is fitted with an emergency stop. To prevent unauthorized persons from using the machine, a key switch can be used to block operation.

Robust finger guards have been installed. For up to and including 6 mm cuts, openings have been made in these guards, allowing the operator to safely get closer to the

blade.